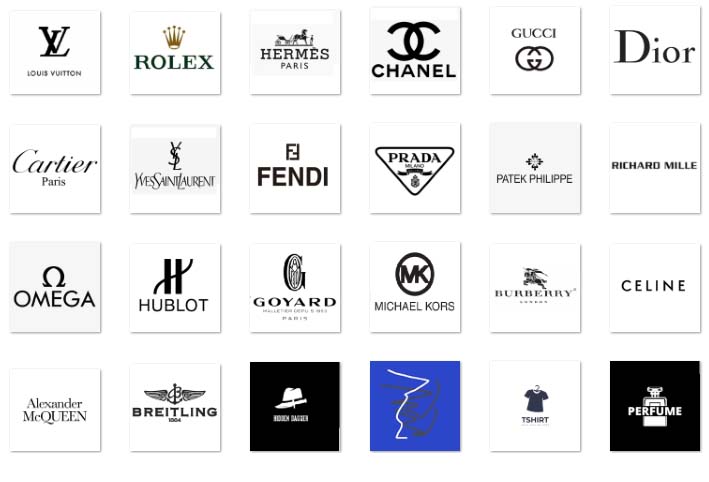

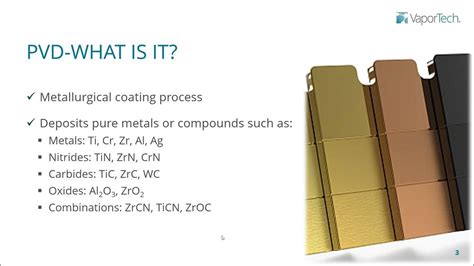

what does pvd stand for in watches In short: PVD or Physical Vapor Deposition, is a process which vaporizes a number of metals, and then binds it on a surface, in layers, in a heated vaccuum. DLC or Diamond Like Carbon, is a different way to use the . DE NEEF® HA Flex LV AF. Next generation, non-phthalate, closed cell, 1-component high performance hydrophobic, Hydro-Active, flexible polyurethane injection grout for waterproofing leaking joints and cracks. Pdf. Product Description. In its uncured form, HA Flex LV AF is a yellow, non-flammable liquid without phthalate plasticisers.

0 · what does pvd coating mean

1 · pvd watch coating purpose

2 · pvd vs dlc price

3 · pvd paint colors

4 · pvd coating for watches

5 · pvd coating colors

6 · does pvd fade over time

7 · difference between pvd and dlc

Absurd Damage: SSB Vegeta has some of the highest solo damage in the entire game, with 236S Guard All Startup 9 Recovery 31 Advantage +3 dealing almost as much damage as a level 1. Lots of meter dump options. Corner Carry: Big Bang Attack Guard All Startup 9 Recovery 31 Advantage +3 cancelling into Superdash along with his .Directions: Many factors contributed to the spread of Islam throughout the world. It is important to distinguish the spread of Islam as a religion from the expansion of Muslim states. Examine the documents below and answer the questions that follow.

First, a description: Physical Vapor Deposition (PVD) is a thin-film coating process that involves depositing various materials on the surface of a watch in a controlled environment. This technique ensures a uniform and . PVD stands for “Physical Vapor Deposition”. PVD is the chemical process where you bind tiny particles to a surface – in this case, watches. More specifically, the process bonds a small layer of metal compounds to the watch. .

PVD or Physical Vapor Deposition is a special technique used to apply a thin, yet very durable layer of material onto a metal surface. In the world of wristwatches, this material . Speaking in the simplest terms, the PVD coating process refers to the application of an extremely thin layer of material onto the surface of components that need to be protected . In short: PVD or Physical Vapor Deposition, is a process which vaporizes a number of metals, and then binds it on a surface, in layers, in a heated vaccuum. DLC or Diamond Like Carbon, is a different way to use the .What Is PVD (Physical Vapor Deposition) On A Watch? In most contexts, PVD stands for Physical Vapor Deposition. This is the name of the chemical process by which a small layer of particles is bound to a surface to create a specialized .

PVD stands for Physical Vapour Deposition, CVD stands for Chemical Vapour Deposition, PLCVD stands for Pulsed Laser Chemical Vapour Deposition and PACVD stands for Plasma Assisted Chemical Vapour Deposition. When selecting the ideal coating for your watch, you may come across two prominent options: Physical Vapour Deposition (PVD) and Diamond-Like Carbon (DLC). .To begin with, the acronym “PVD” stands for Physical Vapor Deposition. The manufacturing process is highly sophisticated and is used to change the color of stainless steel or titanium by coating it with another material. Some brands .

Whether it’s a gold PVD coating giving a stainless steel watch the appearance of a solid gold timepiece, or a functional coating reducing friction and wear on the watch’s gears, PVD has . PVD Coating: The Modern Treatment. PVD is quite an old process of metal plating and its roots can be traced back to 1838 when English scientist Micheal Faraday first used it during his experiments with electricity. Part of the . The acronym PVD is directly related to the world of automatic and quartz watches, but few people know what it refers to. Many watch manufacturers manufacture their parts using metals such as stainless steel or .The enhanced durability and performance that PVD coatings provide have become a standard expectation in the luxury watch market, with consumers increasingly seeking out PVD-coated watches for their superior aesthetics and longevity. Conclusion. In conclusion, PVD is a crucial component in the world of luxury mechanical watches.

PVD: Peripheral Vision Display: PVD: Power Voice Data (bundle) PVD: Portable Vapor Detector: PVD: Providence, RI, USA - TF Green State Airport (Airport Code) PVD: Paravisual Director: PVD: Primary Visual Direction: PVD: Previously Viewed DVD (Digital Versatile Disc) PVD: Paid Vacation Day (business benefit) PVD: Portable Video Device: PVD . 5. what does "complication" mean as it pertains to watches? 6. what does PVD stand for? 7. what does DLC stand for? 8. what are the advantages/disadvantages of PVD and DLC? 9. what are the advantages/disadvantages of Maratac/Zulu/Nato/Bond straps vs leather or rubber straps? 10. what does ETA mean? 11. what's an "ETA conversion"?

Written By Matt Hughes - President - Semicore Equipment, Inc. PVD stands for Physical Vapor Deposition. PVD Coating refers to a variety of thin film deposition techniques where a solid material is vaporized in a . A PVD gold or platinum coating produces brilliant finishes that make watches highly resistant to scratches and scrapes that cause .What does PVD stand for? What does PVD mean? This page is about the various possible meanings of the acronym, abbreviation, shorthand or slang term: PVD. Another technical advantage of PVD is the ability to recreate the appearance of more costly metals such as copper, brass, bronze, and gold. PVD coated metal will not patina. You only need simple cleaning to keep the original copper color looking good. Rose gold PVD can be found in jewelry, and black or gunmetal color is often used for watches. A lot of PVD "Gold" watches are best described as "gold tone". They don't contain any gold. The PVD coating is Titanium Nitride, which is a durable, gold-toned material. These should hold up better than gold plating, since gold is much softer than TiN, but I would expect them to start looking tatty eventually. .

PVD (Physical Vapor Deposition) is a method used to coat watches with a layer of metal. This adds a layer of protection to the watch, increasing its durability and resistance to scratches and other damage. PVD watches have a unique look, often featuring a deep black or bronze color. The coating also reduces the amount of maintenance required to keep the watch looking its best.Choose Invicta’s Watches with PVD Coating: Invicta Stores offers an exquisite collection of watches featuring PVD-coated cases and bracelets. Our timepieces combine style with ruggedness, making them a perfect choice for those seeking a watch that can withstand daily wear and tear. Explore our collection and find the perfect watch with PVD .Inside the plasma-spray physical vapor deposition (PS-PVD) chamber, ceramic powder is introduced into the plasma flame, which vaporizes it and then condenses it on the (cooler) workpiece to form the ceramic coating. PVD process flow diagram. Physical vapor deposition (PVD), sometimes called physical vapor transport (PVT), describes a variety of vacuum .

ysl belt flannels

The coating is formed of vaporized solid materials with a typical PVD process, bound to the watch casing in layers inside a heated vacuum chamber. Depending on the type of material used to coat the watch case, different colors can be achieved, DLC uses carbon as the coating solid, so it only comes in shades of black.

what does pvd coating mean

Our PVD watch coating is very durable and attractive as a watch case and bracelet finish. What is DLC? DLC stands for “Diamond like carbon” and is a type of PVD applied coating. Our DLC watch coating is very black. TitaniumAluminumNitride is a PVD applied coating. The color can range from very light gray to dark charcoal gray.

From rings to watches and everything else in between, the two most common ways to get that iconic gold look comes from gold PVD coating and gold plating. 541.388.3456 . What I’ve run into as a jeweler is clients . Benefits of PVD Coating on Jewelry. Here are all the advantages of using PVD plating for your jewelry: Durability: PVD coating provides a highly durable and scratch-resistant layer that protects the jewelry from wear and .What is PVD Coating and How Does it Work? PVD coating is a thin film deposition process that involves the vaporization of solid materials in a vacuum chamber. These vaporized materials then condense on the surface of the .

used cartier bangle

The object of the exercise in all cases is to keep your watch looking as good as possible, for as long as possible while utilising the most suitable materials for the design of watch. While PVD and DLC seem to be the 'buzz words' in the watch industry at the moment, there are many, many more surface coatings that perform specific tasks in .Peripheral vascular disease (PVD) is a slow and progressive disorder of the blood vessels. Narrowing, blockage, or spasms in a blood vessel can cause PVD. PVD may affect any blood vessel outside of the heart. This includes the arteries, veins, or lymphatic vessels. Single-Piece Nylon (pull-through) watch straps are by far the most famous and most liked straps for watch enthusiasts, who like to wear individual watch straps on their timepieces. You can find nylon straps on any watch, from 100€, to 8000€ Rolexes, up to 50,000€ Patek Philippe watches.PVD, and to check your retina for any holes or tears. Your eyes will be examined with a ‘slit lamp’, a type of microscope found in eye clinics. The light from the slit lamp will not damage your eyes. It seems very bright because your pupils are bigger. They’ll return to their normal size after about 6 .

So steel watch cases would need to be rehardened afterward, increasing the cost and reducing the practicality of a CVD-applied coating in that instance. That said, some brands have used CVD-applied coatings for watch cases, but PVD-applied coatings are more common. So there we have a summary of the CVD coating process. "When we use a coating to achieve a design objective, we only use ionic plating technology. It’s as tough as our watches. Our fans deserve nothing less." - Chaz Chazanow Co-Founder at LIV Watches ENTER IP COATING. Ion plating (IP) is to electroplating as the latter was to foil plating. It was a quantum leap forward. However, if you plan to get a black or dark grey finish for your watch, then you can keep both DLC and PVD as an open option. Pros and Cons of PVD Coating. Even though PVD coating is one of the more popular choices in the watch industry, it does come with its fair share of advantages and disadvantages. With its dive watches well-established, the Seiko 5 collection branched out into military-flavored field watches in late 2023, installing the popular Caliber 4R34 into a new 39.4mm steel case (black PVD-coated in the Ref. SSK025 model) with a reduced but still robust water resistance of 100 meters.

It will stand up to more than regular PVD, and the thicker the application, the more it will stand up to. However, much like Sinn's tegimentation process for hardening the outside of their cases, the underlying material is still softer, so it's not going to be as hard as it would be if the entire part was a single solid of that harder material.Furthermore, re-coating a watch is not something that is commonly done, which can be an issue if you want to get your scratched-up watch back to looking flawless again. But does a DLC watch scratch, and will it leave bright steel marks on the watch as the coating disappears? The answer is that this can be an issue with some PVD-coated watches .

pvd watch coating purpose

Here are all the drops from dueling Elegant Mai at Level 40. Exclusively Available to Subscribers Try it now for $1. Amazoness Princess (UR) Swift Birdman Joe (SR) Queen's Pawn (SR) Amazoness.The principle aim of DECO Industrial Gloves is to manufacture electrical insulating gloves that adhere to and surpass all standards required (AS2225, IEC60903, ASTM). Phone: (03) 9770 4199, Email: [email protected], Enquire: https://decogloves.com.au/Contact.

what does pvd stand for in watches|pvd coating colors